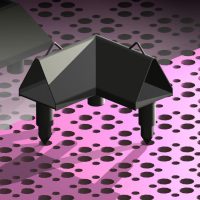

Refueling Shoehorn

The Master-Lee Engineered Products Refueling Shoehorn ensures safe and quick positioning of fuel on the reactor vessel core plate during refueling operations.

Insertion of a bowed or twisted nuclear fuel assembly into its core location can be a difficult and often timely task. The risks of snagging grid straps of adjacent fuel assemblies is an inherent risk during this evolution. Placing EPI’s Refueling Shoehorn next to the fuel assembly’s core location will dramatically improve results and save you valuable time.

Made of stainless steel, the smooth angled sides of the Refueling Shoehorn are machined for damage-free contact with the fuel assembly. Every Master-Lee designed Refueling Shoehorn is treated with ARMOLOY® coating. Applying this surface finishing material to our products yields the following benefits:

– Slippery, smooth surface finish greatly enhancing decontamination process

– Surface hardness of 78 Rc

– Enhanced corrosion resistance

– Reduced wear and friction

The Refueling Shoehorn’s tapered locating pins easily seat within the core plate flow holes, allowing NO movement. When properly seated in the core plate flow holes, the shoehorn will only make contact with the bottom nozzle of the fuel assembly (and not the fuel rods).

Two nylon ropes (or stainless steel cables) attached to the self-centering lifting bail enables the operator to simply lift, move and seat the Refueling Shoehorn. To use the shoehorn, the operator simply lowers it to the adjacent location of the Fuel Assembly’s next core location. The shoehorn will guide the bottom nozzle the final few inches onto its core plate guide pins.

To maximize your time savings, consider using one of our Auxiliary Refueling Bridges for your RF Shoehorn maneuvers.

Please contact us for pricing.