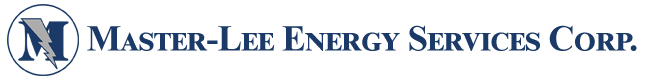

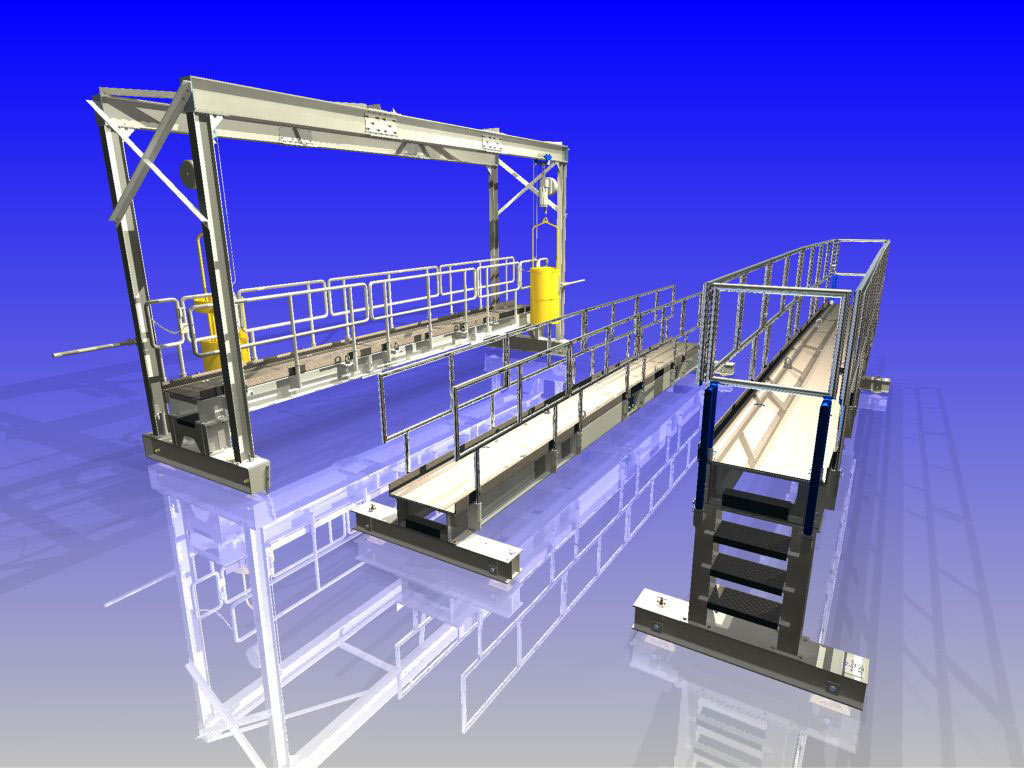

Refueling Auxiliary Bridge

The Master-Lee Engineered Products Auxiliary Refueling Bridge is the logical and practical solution to expedite your nuclear refueling process.

Designed for personnel to manipulate Underwater Lighting and Refueling Shoehorns, our bridge will eliminate crucial downtime when used in tandem with the manipulator crane. Additionally, MLEP’s Auxiliary Refueling Bridge has routinely been used for supporting a variety of reactor/refueling cavity projects, such as FME retrieval (FOSAR), cavity decontamination, and vessel inspections.

Built to accommodate the industry’s dynamic work environment, MLEP’s Auxiliary Refueling Bridge is engineered to your specific criteria (height, rail-to-rail length, number of sections, etc.), load limit, and seismic response spectra (if applicable).

Some of the key design features of Master-Lee’s bridge:

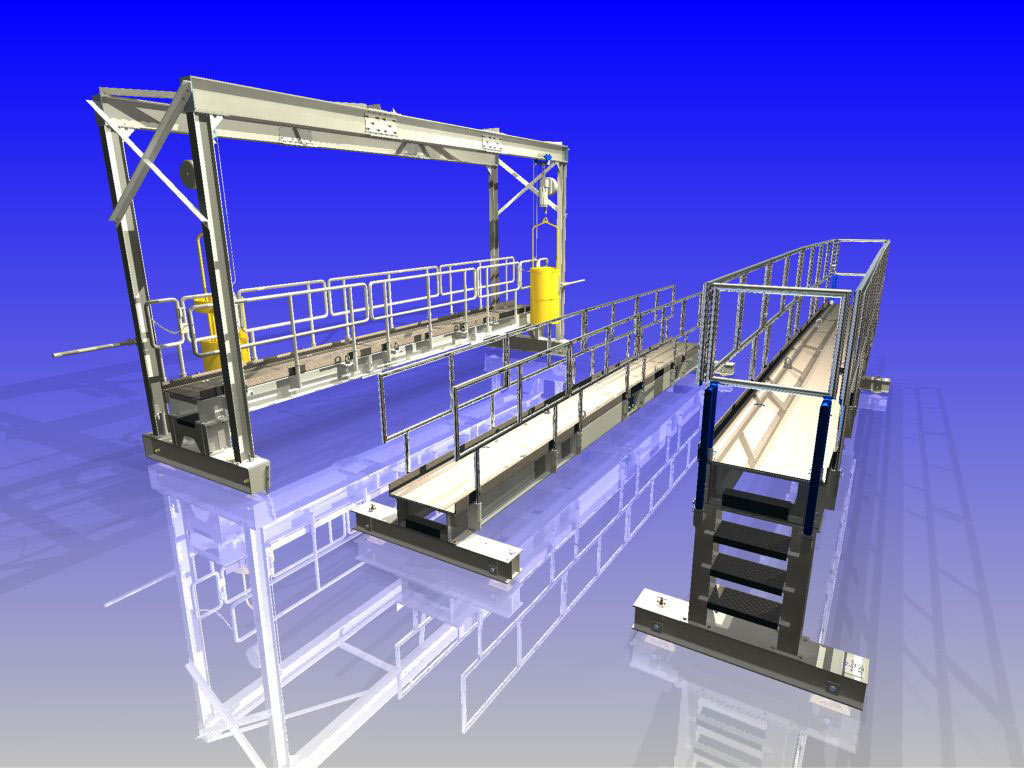

- Aluminum, 2-Piece construction

- 4″ high toe kick-plates

- Slip-Resistant decking

- OSHA Handrails (removable)

- 36″ wide walkway (standard)

- Requires less than 15 lbs. of force to move

- NO CRABBING or BINDING

- Assembly time at less than 2 hours

- Stress analysis and load testing performed

- Seismic analysis

- 3-Piece construction

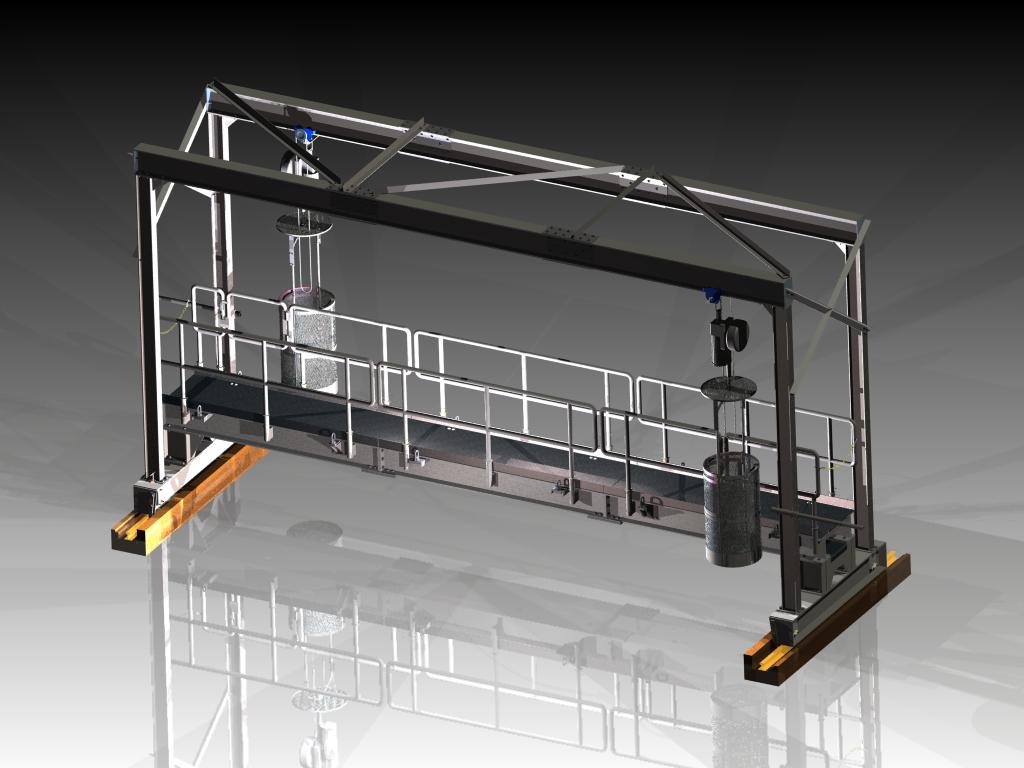

- Super-Structure

- Storage containers

- Carbon steel construction

- Swingates

Let us design a bridge for your next outage. Please call and discuss the design options with our engineers.